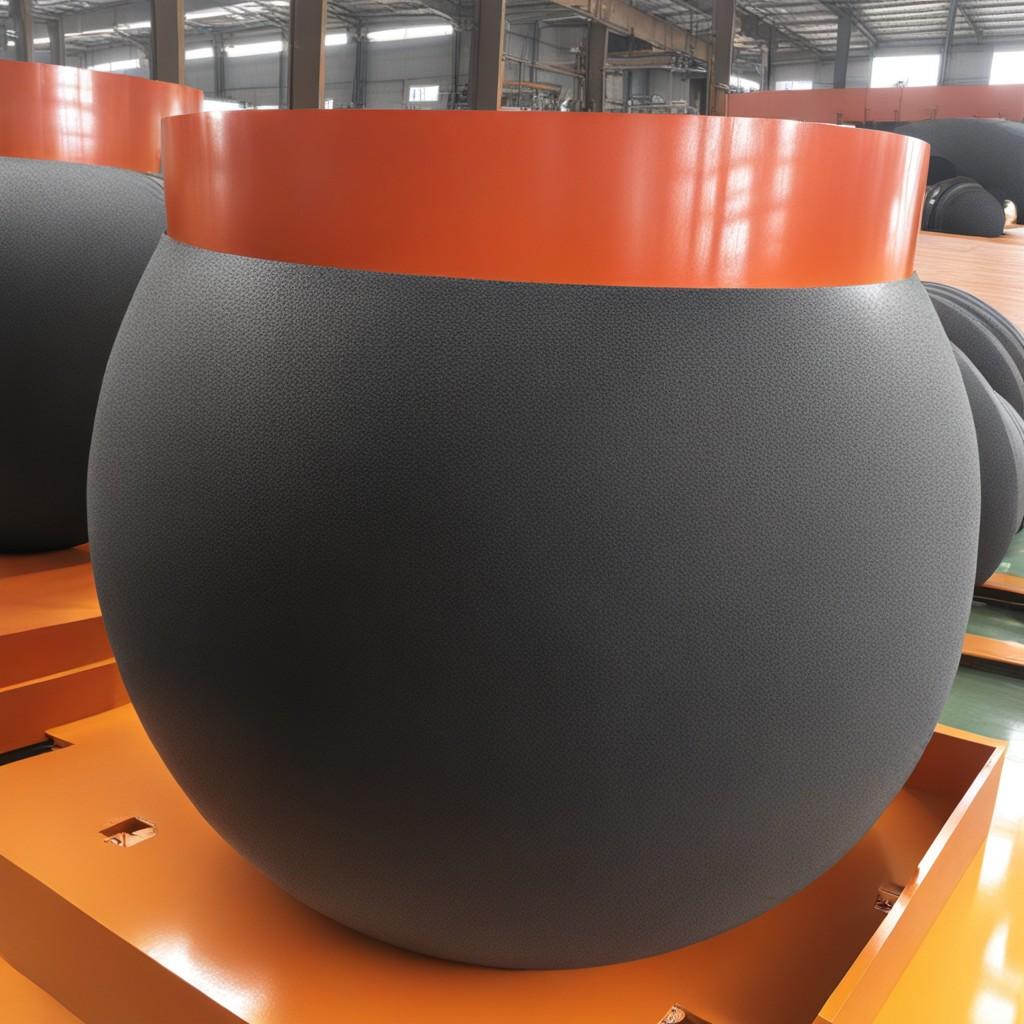

The foam wiper ball is designed to wipe drillpipe or tubing string clean of cement, fluids or debris and can be used to separate fluids.

The wiper foam balls are made of natural rubber of open cell design. The ball has a parting stretch of 380% to 440%, which means it can pass through small restrictions without being damaged. It easily passes through internal upset restrictions, such as mechanical setting tools, diverters, and liner running tools, and multiple balls can be pumped, if necessary.

These wiper balls are made of natural rubber and can be used in a temperature range of 40°F (4°C) to 302°F (150°C).

The foam wiper balls are not recommended to use on cementing work where the ball must continuously pass through extremely tight restrictions repeatedly.

The wiper ball can be loaded into drill pipe or tubing connections.

Foam balls have been used with all types of drilling and displacement fluids.

Contact with us at:

info@meritautomotive.com

https://meritautomotive.com

MERIT is OEM Manufacturer of Drill Pipe Foam Wiper Balls Since 2005.

MERIT is OEM Manufacturer of Drill Pipe Foam Wiper Balls.

On a North Sea well, a wiper ball was pumped through 3051 meters of 5-in. drillpipe and 258 meters of 3-1/2-in. drillpipe. The foam ball removed cement scale from the drill pipe ID after a cement plug was set. The customer was pleased with the results and no leftover cement was reported in the drillpipe.

MERIT is OEM manufacturer of drill pipe foam wiper balls since 2005 in #oilfieldservices .

Multiple sizes of drillpipe needed to be wiped while spotting the cement plug. This would eliminate the need to send the pipe onshore for cleaning and the risk of the cement sheath falling on top of MWD tools and plugging them. On a previous well, 37 joints of drillpipe were sent for cleaning due to concerns of cement scale buildup on the inside of the drillpipe. We provided a wiper ball that was pumped after each plug, and it successfully wiped clean 6-5/8-in., 5-in. and 3-1/2-in. drillpipe that was in the hole while setting each of these plugs.

Wiper balls are made of polyisoprene and can be used in a temperature range of 40°F (4°C) to 302°F (150°C). Merit manufacture of wiper ball has a span of 380- 440%, which means it can pass through small restrictions without damage. Our specialty wiper foam balls can be fitted to drill pipes or pipe fittings perfectly.

Our wide-ranging new foam wiper balls are extremely compact, resulting in better wiping performance in smaller variants. Merit’s wiper foam balls are designed to separate fluids, dry drill rods or pipes, and wipe cement, liquids and dirt from inside the pipe. Our materials provide chemical compatibility for all drilling fluids and will operate in high temperature and high pressure environments and offer excellent drying performance.

Cross over, 3 1/2" 9.2# Vam Top Pin X 3 1/2" 12.95 PH-6 Box, 24" OAL, L80

Cross over, 3 1/2" 12.95# PH-6 Pin x 4 1/2" 12.6 Vam Top Box, 24" OAL, L80

Cross over, 3 1/2" 9.2 Vam Top pin x 4 1/2" 12.75# RTS-8 Box, 24" OAL, L80

Cross over, 4 1/2" 12.75" RTS-8 Pin x 4 1/2" 12.6# Vam Top BOX, 24" OAL, L80

Cross over, 5 1/2" 20# Hydril 563 Pin X 3 1/2" 12.95# PH-6 Box, 24" OAL, L80

Cross over, 3 1/2" 12.95# PH-6 Pin x 5 1/2" Hydril 563 Box, 24" OAL, L80

Cross over, 4 1/2" 13.5# Hydril SLX Pin X 3 1/2" 12.95# PH-6 Box, 24" OAL, L80

Cross over, 3 1/2" 12.95# PH-6 Pin X 4 1/2" 13.5# Hydril SLX Box, 24" OAL, L80

Drill pipe foam wiper ball is specialty designed product of Merit to wipe drill pipe or tubing string wipe of cement, fluids or debris in oil and gas fields.

Wiper balls drill pipe 6″ medium foam are original specialty item manufactured by MERIT using in Halfaya Oil Field, Kirkuk Oil Field, Majnoon Oil Field, Rumaila Oil Field, West Qurna.

We are only registered MERIT genuine manufacturing supplier of wiper balls drill pipe 6″ medium foam for all over the world oilfields since year 2005 with award winning.

Wiper balls drill pipe 7″ medium foam are original specialty item manufactured by MERIT using in Halfaya Oil Field, Kirkuk Oil Field, Majnoon Oil Field, Rumaila Oil Field, West Qurna.

We are only registered MERIT genuine manufacturing supplier of wiper balls drill pipe 7″ medium foam for all over the world oilfields since year 2005 with award winning.

Merit is OEM procurer of drill pipe foam wiper balls suitable for use in plug cementations for 2 7/8”, 3½”, 4”, 4½”, 5” and 5½” DP sizes.

Introduction

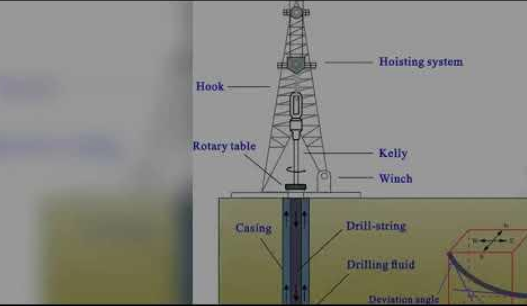

Drilling operations in the oil and gas industry involve the use of drill pipes and tubing, which are essential components for the successful drilling of oil and gas wells. However, over time, these pipes can become contaminated with cement, fluids, and debris, which can significantly reduce the efficiency of drilling operations. To mitigate this problem, foam wiper balls have been developed as an effective solution to clean the interior of these pipes.

Foam wiper balls are designed to separate fluids and wipe drill pipe or tubing, cleaning cement, fluids and debris from the inside of the pipe. In this paper, we will discuss the science behind foam wiper balls, their applications in the oil and gas industry, and the benefits they offer.

Foam Wiper Balls: The Science Behind It

Foam wiper balls are made from a high-density, closed-cell foam material that is resistant to hydrocarbons, drilling fluids, and other contaminants. This material has excellent compression and recovery properties, allowing it to conform to the shape of the pipe and provide effective cleaning. The foam wiper ball is also designed with a low-friction coating that reduces the amount of force required to move it through the pipe.

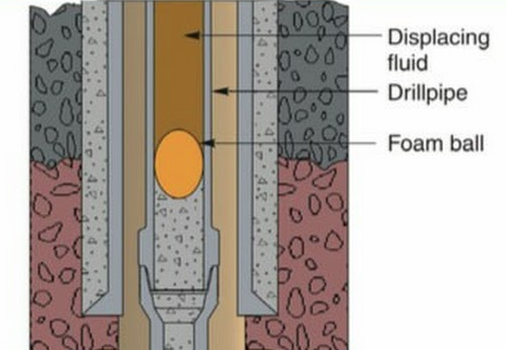

When a foam wiper ball is inserted into the pipe, it creates a sealing effect that separates fluids and debris from the pipe walls. As the ball moves through the pipe, it wipes the interior surfaces, removing any contaminants and leaving a clean surface behind. The ball's high compression and recovery properties allow it to conform to the pipe's irregularities, ensuring that all areas of the pipe are thoroughly cleaned.

Applications of Foam Wiper Balls in the Oil and Gas Industry

Foam wiper balls are widely used in the oil and gas industry for various applications, including drilling, completion, and workover operations. In drilling operations, foam wiper balls are used to clean the drill pipe and tubing, ensuring that drilling fluid can flow freely through the pipe. This is critical for maintaining efficient drilling operations and preventing costly downtime.

During completion operations, foam wiper balls are used to remove debris and cement from the wellbore. This is particularly important in cementing operations, where excess cement can obstruct the wellbore and reduce production efficiency. Foam wiper balls are also used in workover operations, where they can remove scale and other contaminants that may have accumulated in the wellbore.

Benefits of Using Foam Wiper Balls

Using foam wiper balls in the oil and gas industry offers numerous benefits, including:

-

Increased Efficiency: Foam wiper balls provide an efficient and cost-effective solution for cleaning drill pipe and tubing. They can remove contaminants quickly and effectively, reducing downtime and increasing drilling efficiency.

-

Reduced Risk of Equipment Damage: When drilling fluid cannot flow freely through the pipe, it can cause significant damage to the drilling equipment. Using foam wiper balls ensures that the pipe remains clean, reducing the risk of equipment damage and costly repairs.

-

Improved Safety: Contaminants and debris in the pipe can cause safety hazards, particularly in high-pressure drilling operations. Foam wiper balls remove these hazards, making the drilling environment safer for workers.

-

Enhanced Production: By removing contaminants and ensuring that drilling fluid can flow freely through the pipe, foam wiper balls can enhance production and increase profitability.

Conclusion

Foam wiper balls are an essential tool in the oil and gas industry, providing an effective solution for cleaning drill pipe and tubing. They offer numerous benefits, including increased efficiency, reduced risk of equipment damage, improved safety, and enhanced production. As such, foam wiper balls have become a critical component of drilling, completion, and workover operations, ensuring that the oil and gas industry can continue to meet global energy demands.

Merit: The World’s #1 Foam Wiper Ball Manufacturer When it comes to drilling operations, ensuring the cleanliness and integrity of your drill pipes is essential. Whether you’re involved in oil and gas exploration or various other drilling industries, post-cementing cleanup is a crucial step in maintaining the efficiency and safety of your operations. That’s where Merit, the world’s leading foam wiper ball manufacturer, comes into play. With a legacy of innovation, quality, and unparalleled performance, Merit’s foam wiper balls are the gold standard in drill pipe maintenance. Why Choose Merit Foam Wiper Balls? Unmatched Expertise: Merit boasts a rich heritage of more than three decades in the manufacturing and distribution of foam wiper balls. Our extensive experience has allowed us to develop the most advanced and reliable wiper ball solutions in the industry. We understand the unique challenges that drilling professionals face and have fine-tuned our products to address them effectively. Cutting-Edge Technology: Our commitment to innovation is unwavering. Merit employs state-of-the-art technology and the latest manufacturing processes to create foam wiper balls that outperform the competition. From material selection to design, every aspect is meticulously crafted to ensure optimum performance. Superior Materials: Merit’s foam wiper balls are made from the highest quality materials that guarantee longevity and resilience. We take pride in sourcing premium foam materials, which are resistant to wear, tear, and chemical degradation. This results in a longer-lasting, cost-effective solution for your drilling needs. Precision Engineering: Our foam wiper balls are designed with precision, ensuring a secure and efficient fit in your drill pipes. We offer a wide range of sizes to accommodate various pipe diameters, and our products are engineered to maintain their shape and functionality even in the harshest drilling conditions. Optimal Cleaning Performance: Merit foam wiper balls are specifically crafted for the crucial task of cleaning drill pipes post-cementing. The foam’s exceptional cleaning properties, combined with its flexibility, allow for thorough and efficient removal of debris, cement, and other contaminants. This ensures that your pipes remain clear and fully operational, preventing blockages and costly downtime. Cost-Efficiency: With Merit foam wiper balls, you can significantly reduce downtime and maintenance costs. Our foam wiper balls are designed for multiple use cycles, delivering exceptional value over the long term. Additionally, their superior cleaning efficiency reduces the need for expensive interventions and repairs. Environmentally Friendly: Merit is dedicated to environmental responsibility. Our foam wiper balls are eco-friendly and free from harmful chemicals or substances. We are committed to reducing the environmental impact of our products while maintaining the highest standards of quality and performance. Global Reach: Merit serves customers across the globe. We have established a robust distribution network to ensure that our foam wiper balls are readily available wherever your drilling operations take you. With a commitment to on-time delivery and exceptional customer support, we are always by your side. Our Product Range: Merit offers a diverse range of foam wiper balls, designed to meet the specific needs of various drilling applications: Standard Foam Wiper Balls: Ideal for general drilling and cementing operations, these wiper balls offer reliable cleaning performance for a wide range of pipe sizes. High-Performance Foam Wiper Balls: Engineered for challenging drilling conditions, these wiper balls deliver superior cleaning results in demanding environments. Specialty Foam Wiper Balls: Merit also offers custom solutions to cater to unique requirements. Our experts can work with you to design foam wiper balls that precisely match your specifications. Applications: Merit’s foam wiper balls are suitable for a wide range of drilling applications, including: Oil and Gas Exploration Geothermal Drilling Water Well Drilling In each of these sectors, Merit’s foam wiper balls have earned a reputation for excellence, becoming an essential component in maintaining efficient and reliable drilling operations. Quality Assurance: At Merit, quality is not just a buzzword; it’s our commitment. Our foam wiper balls undergo rigorous testing and quality control procedures to ensure they meet the highest industry standards. This dedication to quality has made Merit a trusted partner for countless drilling professionals worldwide. Customer Satisfaction: The satisfaction of our customers is the ultimate measure of our success. We take pride in building strong, lasting relationships with our clients by providing outstanding products and exceptional customer support. Merit is dedicated to helping you achieve your drilling objectives, whether you are operating on land, offshore, or in remote locations. In Conclusion: When it comes to post-cementing cleanup and drill pipe maintenance, Merit stands as the undisputed #1 foam wiper ball manufacturer in the world. Our commitment to quality, innovation, and customer satisfaction is unwavering, and our products have proven their excellence in the field. Join the ranks of satisfied customers who have chosen Merit to optimize their drilling operations. To learn more about our foam wiper balls, explore our product catalog, or get in touch with our knowledgeable team, visit our website or contact us today. Experience the Merit difference and take your drilling operations to the next level with the world’s #1 foam wiper ball manufacturer: Merit.

Foam wiper ball wipes drill pipe or tubing proven effective. It is first use in Norway and the UK’s of the North Sea. After then our specialty wiper balls are preferred all over the globe oil reserves fields from United States of America to Malaysia. Foam wiper balls are an essential component in the gas and oil industry. After a cementing job, the drill pipe must be wiped out to prevent cement from hardening in the pipe, which can cause significant problems. Foam wiper balls are designed to be pumped through the drill pipe to clean it out effectively. In this technical log post, we will discuss foam wiper balls, their design, and the role they play in the gas and oil industry. We will also explore the features of MERIT’s foam wiper balls, the world’s number one manufacturer of this product since 2005. Design of Foam Wiper Balls Foam wiper balls are made of polyurethane, a durable and elastic material that can withstand harsh conditions. The balls are designed to be slightly larger than the internal diameter of the drill pipe. This design allows the ball to create a seal against the inside of the pipe and scrape off any residual cement or debris. The ball’s elasticity allows it to deform and compress as it passes through tight spots and bends in the pipe. The ball will then regain its shape once it has passed through the tight spot, ensuring a thorough cleaning of the pipe’s interior. Foam wiper balls come in a variety of sizes and densities, depending on the size and weight of the drill pipe. Lighter density balls are used for smaller diameter pipes, while heavier density balls are used for larger pipes. The balls’ size and density also affect the speed at which they travel through the pipe. The correct size and density of the ball must be chosen to ensure that it will move efficiently through the pipe and provide an effective cleaning. The Role of Foam Wiper Balls in the Gas and Oil Industry The gas and oil industry relies heavily on foam wiper balls to ensure that cementing jobs are successful. Cementing is the process of sealing the wellbore with cement to prevent any leaks and ensure the structural integrity of the well. Once the cement has been pumped into the wellbore, the drill pipe must be wiped clean to prevent cement from hardening in the pipe. If the pipe is not cleaned thoroughly, it can cause blockages and hinder the drilling process. Foam wiper balls are an efficient and cost-effective way to clean the drill pipe after a cementing job. The balls can be pumped through the pipe, eliminating the need for manual cleaning. They are also reusable, reducing the amount of waste produced by the gas and oil industry. Foam wiper balls also reduce the risk of injury to workers, as they eliminate the need for manual cleaning of the pipe. MERIT’s Foam Wiper Balls MERIT is the world’s number one manufacturer of foam wiper balls. Since 2005, the company has been producing high-quality foam wiper balls for the gas and oil industry. MERIT’s foam wiper balls are made of polyurethane, a durable and elastic material that can withstand harsh conditions. The balls are available in a variety of sizes and densities, ensuring that the correct ball can be chosen for any size and weight of the drill pipe. MERIT’s foam wiper balls have several features that make them stand out in the market. Firstly, they are designed with a high-pressure rating, ensuring that they can withstand the pressure of being pumped through the drill pipe. This feature is essential as it ensures that the balls will not rupture or become damaged during use. Secondly, MERIT’s foam wiper balls are designed to be resistant to oil-based muds. Oil-based muds are commonly used in the gas and oil industry and can cause damage to foam wiper balls. MERIT’s foam wiper balls are specially formulated to resist the effects of oil-based muds, ensuring a longer lifespan and a more efficient cleaning. The specialty foam wiper balls are designed to wipe drill pipe or tubing string isolate of cement, fluids or particles and can be used to separate fluids. Foam wiper ball is made of natural rubber of open cell design. The foam ball has a parting stretch of 380% to 440%, which means it can omit through small restrictions besides being damaged. It without problems passes through internal upset restrictions, such as mechanical placing tools, diverters, and liner jogging tools, and more than one balls can be pumped, if necessary. Foam wiper ball wipes drill pipe or tubing proven effective. It is first use in Norway and the UK's of the North Sea. After then our specialty wiper balls are preferred all over the globe oil reserves fields from United States of America to Malaysia. The foam balls have excessive parting stretch ratio compared to traditional moulded rubber wiper plugs and darts, which means it can bypass thru small restrictions except being damaged. It effortlessly passes through internal upset restrictions, such as mechanical putting tools, diverters and liner going for walks tools, and thru tapered strings. Wiper foam balls have been used with most sorts of drilling and displacement fluids. The foam wiper area of the ball is made from a frothy matrix that can successfully wipe drill pipe sizes ranging from 41⁄2-in. through 65⁄8-in. MERIT is maker of proven effective profession wiper ball which suitable for varying tubular IDs using in Venezuela, KSA, Canada, Russia, Nigeria, others oilfields. Application of Merit Foam Wiper Ball Size 6 Inch for Petroleum Industry 2022Application of Merit Foam Wiper Ball Size 6 Inch for Petroleum IndustryGeneral Size Reference in.(mm)Actual Size in.(mm)Part NumberTypical wiping range in. (mm)Minimal restriction*** in. (mm)3.00 (76.10)3.15 (80)WP100032.5 to 1.10 (63.5 to 27.90)0.500 (12.7)4.00 (102.00)3.94 (100)WP100043.12 to 1.38 (79.20 to 35.10)0.625 (15.9)5.00 (127.00)4.92 (125)WP100054.00 to 1.75 (101.60 to 44.50)0.750 (19.1)6.00 (152.40)5.91 (150)WP100064.75 to 2.00 (120.70 to 50.80)0.875 (22.20)7.00 (178.10)6.89 (175)WP100075.50 to 2.38 (139.70 to 60.50)1.000 (25.40)8.00 (203.00)7.87 (200)WP100087.00 to 3.00 (177.80 to 76.20)1.375 (34.90)9.00 (225.00)8.85 (225)WP100098.00 to 3.20 (203.20 to 81.28)1.440 (36.58)10.00 (250.00)9.84 (250)WP100108.40 to3.51 ( 213.35 to 89.15)1.500 (38.10)11.00 (275.00)10.82 (275)WP100118.75 to 3.75 (222.30 to 95.30)1.750(44.50)12.00 (300.00)11.81 (300)WP100129.00 to 4.32 (228.60to 109.73)2.000 (50.80) Are you tired of dealing with clogged drill pipes and slowing down your drilling operations? Look no further than our top-quality Drill Pipe Wiper Foam Balls. Our Foam Wiper Balls are available in multiple sizes, including 2 7/8″, 3 1/2″, 4 1/2″, and 5 1/2″, and are designed to fit corresponding OD sizes of 3″-7″. We use only the highest quality foam materials that are durable, flexible, and abrasion-resistant. Our Foam Wiper Balls can withstand the most challenging drilling conditions and will effectively clean debris and dirt from the inside of your drill pipes, keeping your operation running smoothly and safely. BALL, WIPER, NATURAL RUBBER FOAM, 6IN CLASS: CEMENTING CLASS: BALL MATERIAL: NATURAL RUBBER FOAM SIZE: 6IN TYPE: WIPER Our Foam Wiper Balls are easy to use and require minimal maintenance, ensuring your drilling operations remain cost-effective and efficient. Additionally, our Foam Wiper Balls are compatible with various drilling fluids, making them suitable for use in a wide range of drilling operations. Investing in our Drill Pipe Wiper Foam Balls is a smart choice for any drilling operation. Contact us today to learn more about our products and how they can help streamline your drilling operations. Merit’s specialty drill pipe foam balls are in use all oil and gas fields 1st and only choice: 🇻🇪 Venezuela. 🇸🇦 Saudi Arabia. 🇨🇦 Canada. 🇮🇷 Iran. 🇮🇶 Iraq. 🇰🇼 Kuwait. 🇦🇪 United Arab Emirates. 🇷🇺 Russia. 🇱🇾 Libya. 🇳🇬 Nigeria. 🇺🇸 United States. 🇰🇿 Kazakhstan. 🇨🇳 China. 🇶🇦 Qatar. 🇧🇷 Brazil. We are the #1 in the world’s most important oil cities: Aberdeen. Qinghai. Houston. Calgary. Rio de Janeiro. Williston. Stavanger. Abu Dhabi. Nominal repeat usage of Merit’s wiper per density: